Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Pistes linéaires pour les robots

Pistes linéaires pour les robots

(2)Linear Tracks for Robots are mechanical systems designed to provide smooth and precise motion along a linear path, enabling robotic arms or gantries to move in a controlled manner. These tracks are commonly used in automation, manufacturing, and robotic applications where robots need to travel across specific distances or along predefined paths to carry out tasks such as material handling, assembly, or pick and place operations.

Key Features of Linear Tracks for Robots:

-

Smooth Movement: Linear tracks provide a frictionless or low-friction surface that allows robots to move smoothly with minimal resistance.

-

Precision: These tracks are designed to ensure accurate, repeatable movements along a set path. This is crucial for robots involved in tasks such as assembly, packaging, or inspection.

-

Load Capacity: Depending on the design, some linear tracks are capable of handling heavier loads, while others are more suited to lightweight operations. This can depend on the materials used, the size of the track, and the type of rails.

-

Customizable Length and Configuration: Many linear tracks can be customized in terms of length, width, and configuration to meet specific operational needs. They may also include curves, angles, or turns to create more flexible paths.

-

Versatile: Linear tracks are compatible with a wide range of robotic arms, gantries, or other mobile robots. They are used across industries like automotive, electronics, packaging, logistics, and more.

Applications of Linear Tracks in Robotics:

- Material Handling: In warehouses and factories, robots equipped with linear tracks can transport goods or materials from one area to another.

- Assembly Lines: Robots use linear tracks to move components or products along an assembly line, ensuring smooth, repeatable processes.

- Automated Testing or Inspection: Robots that need to move items in and out of testing areas or inspection stations often rely on linear tracks for accurate positioning.

- Pick and Place Operations: Robots that perform pick and place tasks may use linear tracks to transport products to the required location.

Types of Linear Tracks:

-

Straight Linear Tracks: These tracks provide movement in a single straight line, typically used in simpler pick-and-place or material handling applications.

-

Curved or Circular Tracks: These allow for robotic systems to follow a curved or circular path, useful in applications that require more complex movement paths.

-

Flexible Tracks: These systems are designed to be modular, allowing users to adjust the layout of the track based on their needs.

-

Precision Tracks: Used for high-precision applications, these tracks are typically designed to minimize wobble and allow robots to perform tasks that require high levels of accuracy.

Manufacturers and Suppliers:

When sourcing Linear Tracks for Robots, it's important to look for suppliers that offer robust systems designed to withstand the operational environment. Some well-known manufacturers and suppliers of robotic linear tracks include:

- THK

- Igus

- Parker Hannifin

- Misumi

- Bosch Rexroth

These companies often offer a variety of options, including precision linear guides, rail systems, and other robotic automation components, allowing for a customized solution based on the robot's requirements.

If you are considering using linear tracks for a specific robotic application, it is recommended to evaluate the following:

- Load capacity: Ensure the track can handle the weight of the robot and the items it will be moving.

- Track precision: Choose a system that meets the required level of accuracy for your task.

- Durability: Consider materials and coatings that can withstand wear and tear, especially in harsh environments.

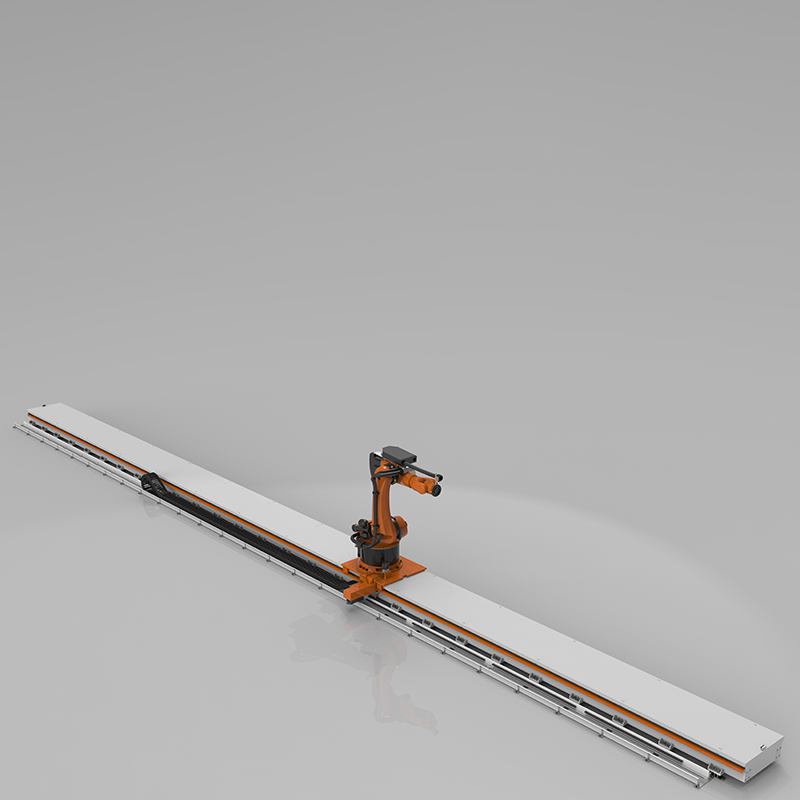

Robot semi-fermé septième axe

Le septième axe du robot semi-fermé est une solution robuste pour l'automatisation industrielle, offrant un système de mouvement linéaire fiable et durable capable de prendre en charge des charges lourdes dans des environnements automatisés. Il est conçu pour un fonctionnement à grande vitesse et a des exigences de maintenance faibles, ce qui en fait un excellent choix pour améliorer l'efficacité et l'innocuité de la manutention des matériaux dans diverses industries.

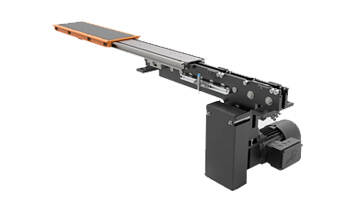

Robot entièrement fermé septième axe

Le Robot Seventh Axe entièrement fermé est un système de piste de sol robot à haute performance et entièrement fermé conçu pour répondre aux exigences strictes de l'automatisation industrielle moderne. Cette solution robuste du 7e axe offre une combinaison de fiabilité, de précision et de durabilité, ce qui le rend idéal pour les applications de transport à charge lourde dans diverses industries. Sa conception entièrement fermée garantit une protection optimale pour les composants, améliorant la longévité et les performances du système.